Off-Site Manufacturing, Prefabrication

Off-site manufacturing shortens schedules, reduces costs and material waste. Your project also benefits from the latest advancements in VDC technology, digital modeling and Lean principles to ensure better quality control, productivity, constructability and safety.

Off-Site Manufacturing Capabilities

Discover how you can improve quality control, shorten your project schedule and reduce costs with our off-site manufacturing solutions and just-in-time delivery.

Learn More-

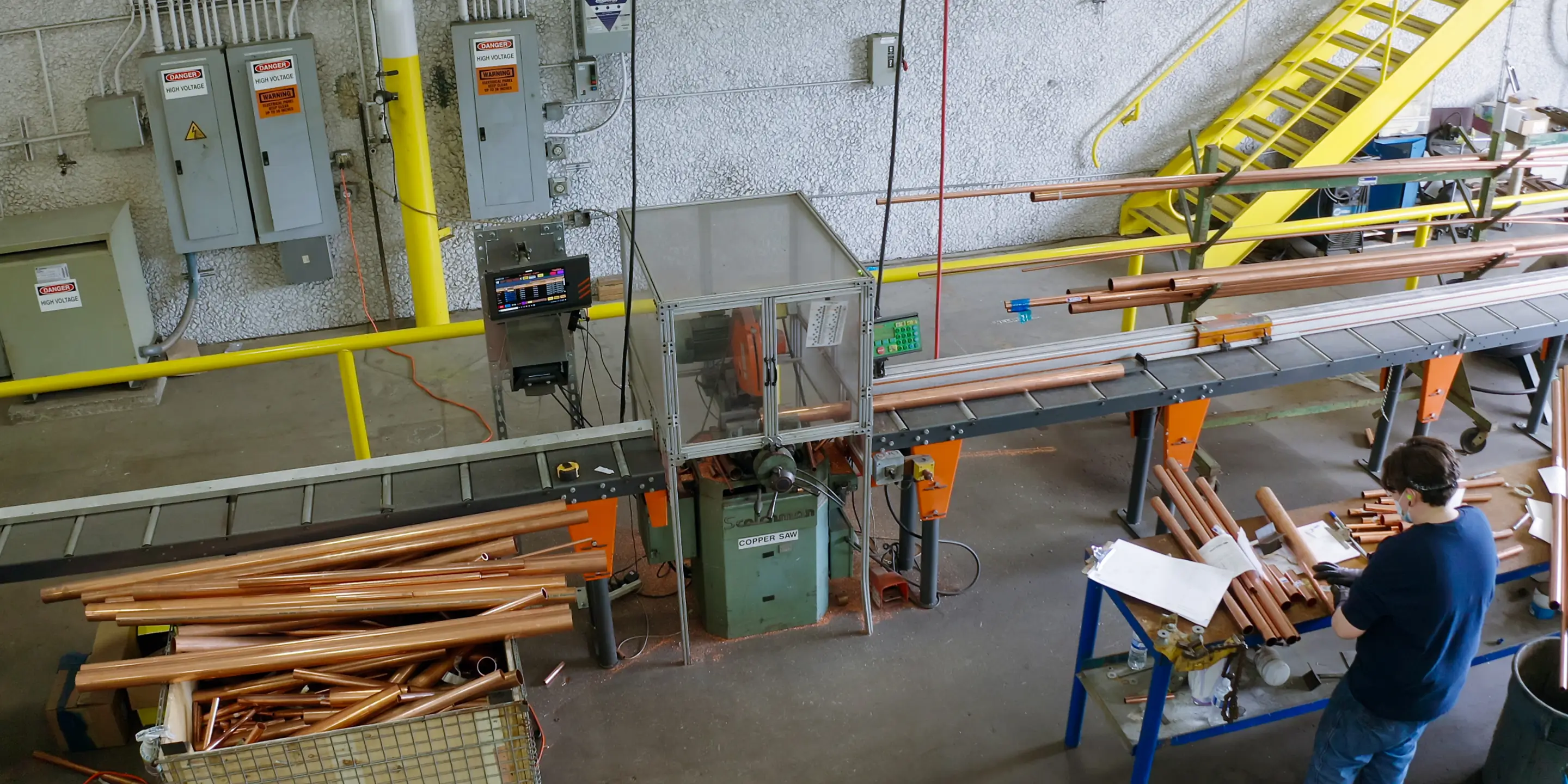

Our Manufacturing Facilities

117,000 Square Feet Dedicated to Manufacturing

At 89,000 square feet, our main prefabrication shop in Dallas, Texas, is one of the largest in the region. Our 28,000-square-foot process piping fabrication facilities in Plano, Texas, include cleanroom capabilities, specialty welding, infrared fusion and skid fabrication. -

Production Capacity

You Won’t Be Waiting on Us

Our shops have the annual capacity to produce:

- 6.5+ million pounds of ductwork and sheet metal

- 275,000 diameter inches of welds

- 2 million feet of fabricated piping assemblies

-

VDC Expertise

Designing from a Digital Model

Get accurate and efficient assemblies according to customer specifications through our ability to create, update and refine digital models. Our team of skilled technicians on the shop floor use Stratus software to view the model and ensure accurate assembly and sectioning throughout the entire prefabrication process.

117,000 Square Feet Dedicated to Manufacturing

You Won’t Be Waiting on Us

Our shops have the annual capacity to produce:

- 6.5+ million pounds of ductwork and sheet metal

- 275,000 diameter inches of welds

- 2 million feet of fabricated piping assemblies

Designing from a Digital Model

Prefabrication Projects

More Projects.jpg?width=1015&name=AltContent-ZeroHarmLogo-1400x1200-v2%20(1).jpg)

Reducing On-Site Safety Risks

We look at every aspect of all prefabrication projects with safety as our top priority. Leveraging off-site manufacturing strengthens our ability to maintain an industry-leading safety record and ensure a safe project site.

Zero Harm CommitmentOff-Site Manufacturing for Your Building

Discover how modular manufacturing and prefabrication can help streamline projects like yours.

-

Data Centers

Quality Control for Mission-Critical Projects

Ensure successful commissioning and reduce costs with digital modeling, a controlled shop environment, and cleanroom assembly options.Our Data Center Services -

Healthcare

Solutions for Complex Medical Buildings

Avoid schedule and budget delays by leveraging cleanroom assembly options, custom medical gas solutions and reduced on-site fabrication.Our Healthcare Experience -

Education

Efficient Workflows for Your Education Projects

Minimize the headaches of restricted workspaces and weather delays and maximize on-site productivity with our data-driven, one-model prefabrication capabilities.Our Education Services -

Sports Venues

Precise Fabrication for Innovative Designs

Get greater accuracy and quality control through advanced prefabrication solutions and VDC technology that bring your venue’s design to life.Our Sports Venue Services -

All Building Types

Off-Site Solutions for Projects Like Yours

We have extensive off-site manufacturing and prefabrication experience in a variety of markets. Take a look at all the markets we serve to discover the capabilities and experience we can bring to your project.The Markets We Serve

Quality Control for Mission-Critical Projects

Solutions for Complex Medical Buildings

Efficient Workflows for Your Education Projects

Precise Fabrication for Innovative Designs

Off-Site Solutions for Projects Like Yours

Expert Services for Your Project

No matter what part of the project we’re responsible for, we’re committed to completing your project safely, on time and on budget.

Mechanical Construction

Expertise, skilled trades and safety compliance for successful project delivery.

Learn moreEngineering

Mitigate design risk and avoid schedule delays with our design-build and design-assist solutions.

Learn MoreProcess Piping

Safely, reliably and quickly bring your products to market with our specialized process piping capabilities.

Learn MorePreconstruction and Estimating

Benefit from our expertise in cost estimation, budget analysis, value engineering, and more — all through efficient one-model VDC collaboration.